Textile Characterization Using the iEM Platform

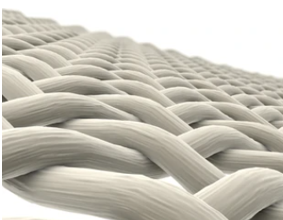

Textiles are flexible products made of textile materials. And textile materials refer to fibers and fiber products, which are yarns, fabrics, and their compounds. Textiles have different properties due to the type and thickness of the fibers. To characterize textile materials, many microscopic techniques have been employed. Among them, electron microscopy (EM) uses electrons rather than light to form an image of the specimens. Scanning electron microscopy (SEM) is a commonly used EM that provides detailed high-resolution and depth-of-field images and is widely used to inspect the structure and surface properties of various textile materials.

Textiles and Textile Materials

Textiles are essential for people's lives and production, especially for clothing and accessories, and are also widely used in many other industries. The shape of the fibers, the source of the fibers, and how the final product is made are three main factors that determine the properties of textiles. Textiles can be made from a wide variety of materials, including manufactured fibers (from polyester or nylon) and natural fibers, namely a class name of fibers of vegetable origin (such as cotton, flax, and ramie), animal origin (such as wool, silk, and specialty furs). Understanding the specific microstructure of fibers can help identify the origin and the type of fibers, and can help design and create novel textile products.

Services Offering at the iEM Platform

Field emission scanning electron microscopy (FESEM) has been demonstrated to be a powerful analytical tool for the study of textile materials. FESEM can provide topographical and elemental information at magnifications of 10x to 300,000x, with a high depth of field. Compared with convention SEM, FESEM yields clearer, less electrostatically distorted images. This is because in the electron gun of a scanning electron microscope, the field-emission cathode provides a narrower probing beam at low and high electron energies, thus improving spatial resolution and minimizing sample charging and damage. In addition, FESEM has several other advantages, including the generation of high-quality, low-voltage images of negligibly charged samples, essentially no need to place a conductive coating on the insulating materials, and the ability to be compatible with energy dispersive x-ray spectroscopy (EDS). At the iEM Platform, our professional scientists can perform analysis, identification, and characterization of a wide variety of textile materials using FESEM.

Choose Creative Biostructure to help you with customized textile characterization, involving:

- Surface analysis of textile materials, the information of coatings, surface debris, manufacturing striations, and damage can be obtained.

- Cross-section characterization of textile fibers, such as the general shape, distribution of pigment particles, depth of dye penetration, and surface feature modifications.

- Compositional analysis and material identification of textiles.

- Checking the quality of the textile fibers, such as performing tensile tests in a SEM.

SEM has many advantages for textiles and their fiber analysis. The images of the sample surfaces show some features that help to identify the origin or even the type of fiber. In particular, SEM analysis can allow us to track and analyze the quality of textile fiber over time. Creative Biostructure supports the use of state-of-the-art instrumentation for the characterization of morphology, chemical composition, and crystalline structure of both natural and man-made solid materials. Textile materials can be investigated for structure, weave, and/or size. If you are interested in our services, please don't hesitate to contact us . We look forward to working with you on your next project.