Dental Implant Analysis Using the iEM Platform

Dental implants are used in dentistry to replace damaged or decayed teeth. In order to ensure rehabilitation biomechanical success, dental implant manufacturing requires not only fine and precise specifications but also measurements and surface analysis at lower scales of dental implants and their fitting components. Scanning electron microscope (SEM) is an electronic microscope that can generate high-quality images of surface structures, which has become an indispensable tool in dental research. At the iEM Platform, Creative Biostructure is committed to providing accurate and reliable dental implant analysis in basic reseach.

Dental Implants

Over the last three decades, dental implants have become an effective way to restore masticatory function in partially or completely edentulous patients. Dental implants are made up of a wide range of materials, such as metals (e.g. Ti alloy stainless steel, and silver), polymers (PTFE, PS, and PMMA), ceramics (e.g. zirconia and alumina), and composites (e.g. CF/carbon and SiC/carbon). Among them, Ti and its alloys have been widely used in the dental field because of their high biocompatibility over other alloy systems. Since dental implants have to withstand different forces applied during mastication, the composite materials have high and superior fatigue performance and are increasingly used as dental implant materials. For example, GF/PMMA is a false tooth designed to completely replace one or more damaged teeth.

In addition, there are different designs of implants, involving different thread sizes and topography. Notably, the surface of dental implants is an important characteristic when treatment planning for dental implants. The micro-rough surfaces of implants are considered to accelerate bone healing by stimulating the deposition of new bone on the fixture, increasing bone-to-implant contact, thus, promoting osseointegration. Therefore, to enhance and speed up bone healing mechanisms, many methods are used to roughen the surface of a dental implant, such as acid-etching and sandblasting. More recently, new surfaces have been introduced, such as the nanostructured calcium-incorporated surfaces.

Dental Implant Analysis at the iEM Platform

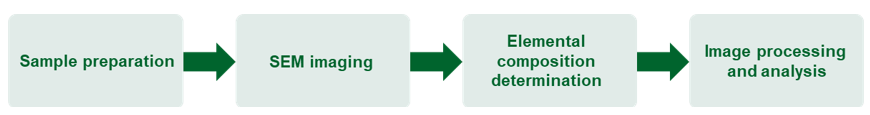

In dental research, dental implants, in particular, need to be microscopically examined to determine safety. Scanning electron microscope (SEM) has become an indispensable tool in dental research. Based on SEM and energy-dispersive X-ray spectroscopy, we are not only able to perform surface characteristics of dental implants, but also identify the composition of materials used in dental implants. Our services include sample preparation, SEM imaging, and energy dispersive X-ray spectroscopy for elemental composition determination as well as image processing and analysis.

- Sample preparation

- SEM imaging

- Elemental composition determination

- Image processing and analysis

The dental implants are imaged using secondary electron imaging with both the secondary electron and backscattered electron detectors.

Energy dispersive x-ray spectroscopy is applied to investigate the elemental composition of implant surfaces.

Automated and market-specific software enables our customers to extract maximum information from images.

Our Specific Services

- Visualization of rough surface characteristics of dental implants.

- Visualization of the thread design.

- Identification of a specimen remaining on a failed dental implant.

- Investigation of dental biomaterials.

SEM has been established as an indispensable tool in dental research. Based on SEM, an unused dental implant and a failed dental implant with unknown material can be compared. Their surface characteristics can be analyzed and the composition of the unknown material can be identified. Thanks for your interest in our dental implant analysis, our techniques or solutions. We are always open to your questions and are happy to support you. Please feel free to contact us.