Metal & Alloy Characterization Using the iEM Platform

Due to their high strength, reliable properties, and processability, metals are widely used in various industries, including construction, automotive, aerospace, medical devices, energy generation, and so on. Metal alloys (consisting of two or more metals), such as steel, solder, brass, and bronze, have improved electrical, mechanical, or electrical properties compared to single metals, thus greatly expanding their range of applications. Metals and alloys have a grain structure, the morphology and chemical composition of hard particles, phase balance, etc. that impact their mechanical properties.

Metal & Alloy Characterization by EM

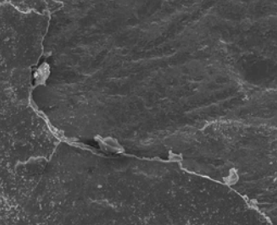

Microstructure characterization is increasingly important for the study of the relationship between chemical composition, process parameters, and mechanical properties of metals/alloys, quality assessment of steels and alloys, and the research and development of new materials. Electron microscopy (EM) is the ideal method for analyzing metals/alloys from the micron to the atomic scale in a multiscale approach. Usually, the microstructure characterization of metals/alloys is performed by scanning electron microscopy (SEM), while the analysis of precipitation phases and grain boundaries of metals/alloys is achieved by transmission electron microscopy (TEM).

Metal & Alloy Characterization at the iEM Platform

At the iEM Platform, we are specialized in the characterization and evaluation of metals/alloys and related materials. Based on scanning electron microscopy/ energy-dispersive X-ray spectroscopy (SEM/EDS) and TEM, we are able to perform alloy phase identification and element distribution analysis, providing morphological characterization and compositional information. The following aspects can be examined by our advanced analytical tools, but are not limited to them,

- Alloy phase identification and distribution analysis.

- Microporosity measurement of metals/alloys.

- Precipitation characterization in metallic materials.

- Non-metallic inclusion characterization in metals/alloys.

- Microstructure characterization during deformation.

Applications of Our Services

- Microstructure characterization of metals/alloys, including aluminum, magnesium, titanium, steels, and other multiple principal element alloys.

- For metallic materials research and development, such as observation of microstructure changes during the processing and study of the relationship between microstructure and fracture resistance.

- Failure analysis of metals/alloys, such as bend failure analysis, corrosion failure analysis, crack propagation analysis, and coating defect analysis.

- Quality assurance of metals and alloy production.

Creative Biostructure has a long experience in metals characterization. Our experienced staff is capable of providing guidance in protocol design for the most appropriate fixation, collection, preparation, and evaluation of samples. Based on improved methods and advanced EM techniques, we are dedicated to providing fast and reliable solutions for a wide range of metal/alloy characterization needs. Please contact us if you would like to have personal expert advice on our microscopy solutions for metal/alloy characterization and analysis. We are always open to your questions and are happy to support you.